Search in Category

Sensors, Photo

Search term required.

Filter Your Search

Country of Origin

Country of Origin

Weight

Weight

No Filtered Results...

Shop by Category

Loading...

Photo Sensors

Viewing Page 1 of 302

(3,016 results)

Bracket: Compact 30 mm Swivel; Black rei

Item #:

SMB30SC

Supplier Part #: 52521

Brand:

Banner Engineering

Bracket: Compact 30 mm Swivel, Black reinforced thermoplastic polyester, Wide Range of Articulation, Hardware included

$16.00

/EA

IN STOCK

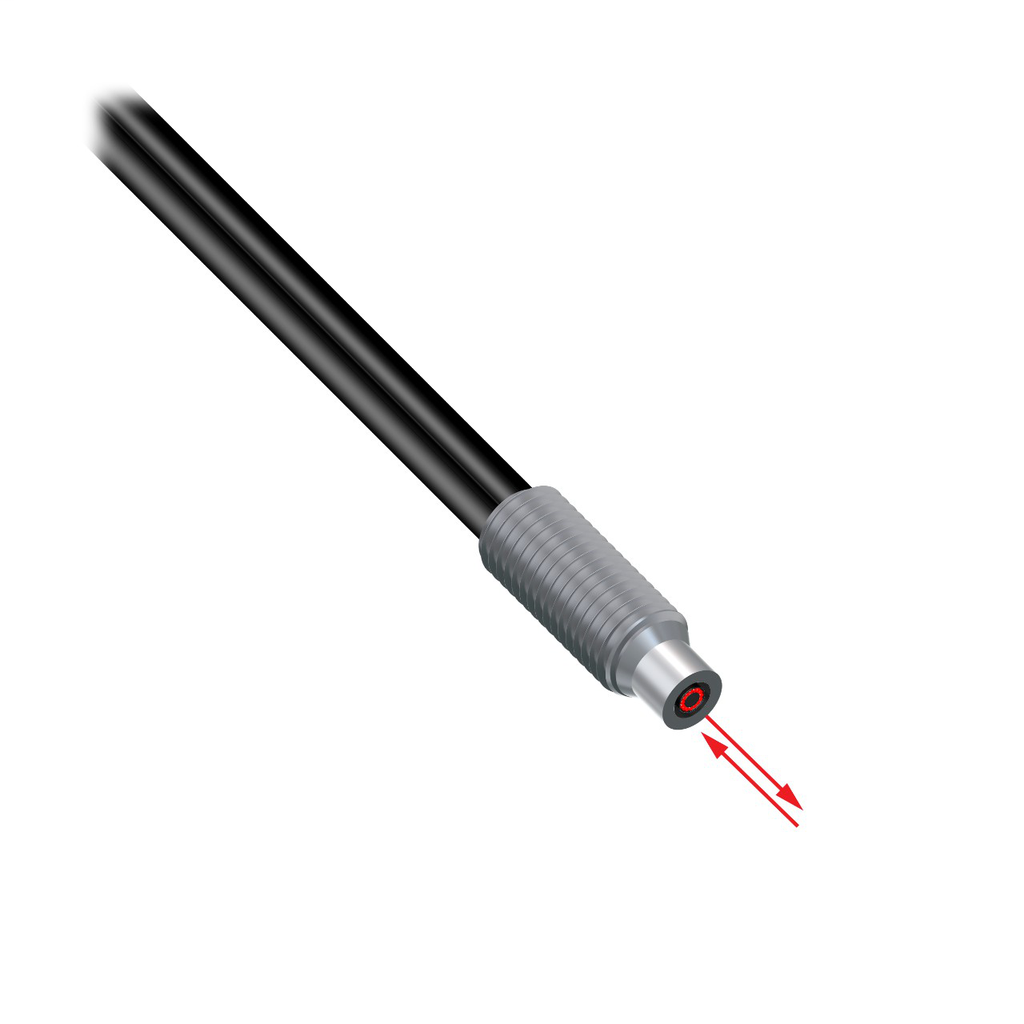

Plastic Fiber; Diffuse Reflective; Core

Item #:

PBCT46U

Supplier Part #: 35214

Brand:

Banner Engineering

Plastic Fiber, Diffuse Reflective, Core Dia.: 1.0 mm & 16 x 0.25 mm, Fiber Length 2 m, Coaxial, Thread, Free cut

$84.00

/EA

NOT CURRENTLY IN STOCK

Retroreflective Target: Rectangular 80 x

Item #:

BRT-80X50CM

Supplier Part #: 73841

Brand:

Banner Engineering

Retroreflector: Rectangle 80x50mm, Microprism - Reflectivity Factor: 1.4, Max Temp = 60 degree C, Plastic - Mounting Screw Hole

$18.00

/EA

NOT CURRENTLY IN STOCK

WORLD-BEAM QS18 LASER POLAR RETRO; Range

Item #:

QS18VP6LLPQ8

Supplier Part #: 73246

Brand:

Banner Engineering

WORLD-BEAM QS18 LASER POLAR RETRO, Range: 0.1 to 10 m, Input: 10-30V dc, Output: Complementary Solid State PNP, Euro-Style Quick-Disconnect Connector

$177.00

/EA

IN STOCK

WORLD-BEAM QS18 Series: Laser Adjustable

Item #:

QS18VP6LAFQ5

Supplier Part #: 73191

Brand:

Banner Engineering

WORLD-BEAM QS18 Series: Laser Adjustable-Field, Range: Cutoff Adjusts Between 30-150 mm, 10-30V dc, Output: Complementary Solid State PNP, 6 in Pigtail Euro-Style Pigtail QD Connector

$233.00

/EA

IN STOCK

Bracket: 30 mm; Material: 12 Gauge Stain

Item #:

SMB30MM

Supplier Part #: 27162

Brand:

Banner Engineering

Bracket: 30mm, Material: 12 Gauge Stainless Steel, Curved mounting slot for versatility/orientation, Clearance for M6 (1/4 in.) hardware

$13.00

/EA

IN STOCK

Bracket: 18 mm Right-Angle-mount; Materi

Item #:

SMB18A

Supplier Part #: 33200

Brand:

Banner Engineering

Bracket: 18 mm Right Angle-mount, Material: 11 Gauge Stainless Steel, Curved mounting slot for versatility/orientation, Clearance for M4 #8 hardware

$11.00

/EA

IN STOCK

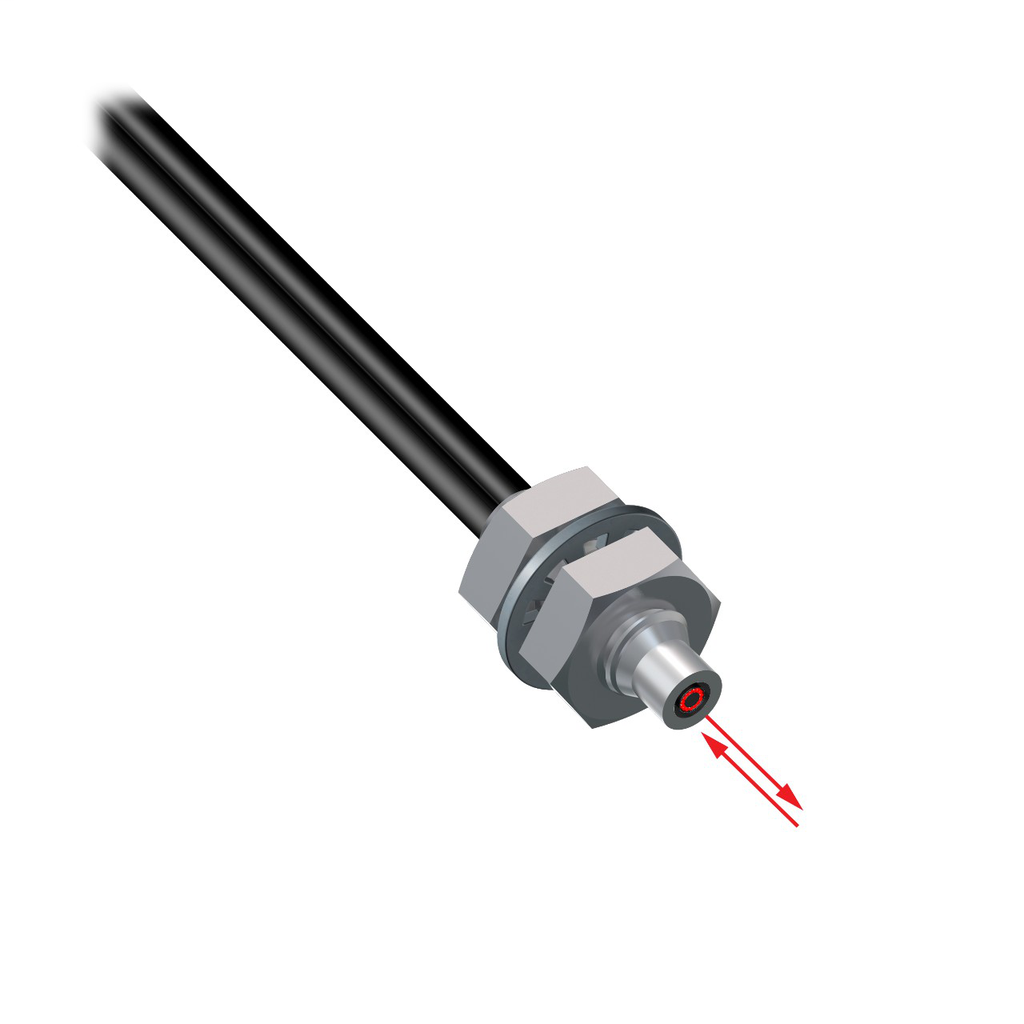

Plastic Fiber, Opposed Mode; Core Dia.:

Item #:

PDIS46UM12

Supplier Part #: 42880

Brand:

Banner Engineering

Plastic Fiber, Opposed Mode, Core Dia.: 1 mm, Fiber Length 2 m, Free cut

$119.00

/EA

IN STOCK

WORLD-BEAM: Polarized Retro; Range: 3.5

Item #:

QS18VP6LPQ8

Supplier Part #: 66452

Brand:

Banner Engineering

WORLD-BEAM: Polarized Retro, Range: 3.5m, Input: 10-30 V dc, Outputs: Complementary PNP, Euro-style Integral Quick-Disconnect

$90.00

/EA

IN STOCK

WORLD-BEAM QS30 Series: Universal Voltag

Item #:

QS30VR3R W/30

Supplier Part #: 73197

Brand:

Banner Engineering

Range: 60m, Input: 12-250V dc or 24-250V ac

$165.00

/EA

IN STOCK

Don't see what you need?

Click here to let us know and we'll help you find what you're looking for.Photo Sensors

As the manufacturing world becomes more integrated with automated technology, it is important to understand how this technology can help you. Industrial automation can make the lives of those working on the production floor easier and help increase a company’s productivity. One type of those helping workers is known as a photoelectric sensor, or photo sensor.What is a Photo Sensor?

A photo sensor is a device that detects a difference in the light level received from the light source. Consisting primarily of an emitter and a receiver, a photoelectric sensor emits light that when interrupted or reflected by the sensing object, it changes the amount of light that arrives at the receiver.Photoelectric sensors come in a variety of forms and can be used in many industries to accomplish a diverse list of tasks. ACD provides many varieties of these sensors, including diffuse-reflective, thru-beam, retro-reflective, and distance-settable sensors.

Types of Photoelectric Sensors

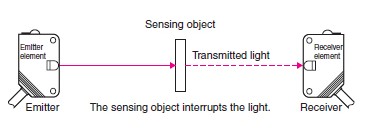

There are three major types of photo sensors: thru-beam, retro-reflective, and diffused. Each sensor is described below and has it’s own strengths and a variety of uses.Thru-Beam Photo Sensors

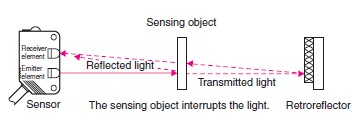

In thru-beam photoelectric sensing, also known as opposed mode, there are two separate devices that are used to make or break a beam. One sensor houses the light emitter while the other houses the receiver. A thru-beam sensor uses object detection by the light beam between the two sensors being interrupted by an object passing through.

Thru-Beam Applications

- Detect objects

- Very small objects

- Opaque objects

- Detect precise location of a specific object

- Detect spliced or overlapped materials

- Detect the contents of a container

- Detect fill levels inside a container

Retroreflective Photo Sensors

In retroreflective photoelectric sensing, both the emitter (or light source) and receiver are in the same housing. This type of sensor works alongside a reflector where when the light is emitted from the sensor and is aimed at the reflector, it is then sent back to the light receiving element. Retroreflective sensors detect the presence of an object when the light path is interrupted.

Retroreflective Applications

- Detect reflective tape at high speeds

- Detect objects moving at high speeds

- Detect large objects

- Sense transparent glass or plastic products

Diffused Photo Sensors

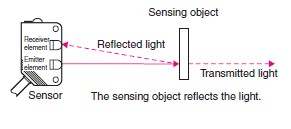

In diffused sensing, also known as optical proximity sensing, the light source and receiver are housed in the same device. Diffused sensors detect objects when the light beam that is emitted towards the target is reflected back to the sensor by the target. With all components in a single housing, this type of sensor is a great option for automation since they are more compact than typical units.

Diffused Applications

- Detect fill levels in a container

- Detect presence of parts, boxes, and other materials

- Detect multiple objects on a conveyor system

- Detect identifying features to determine an object’s orientation

Brand

Brand